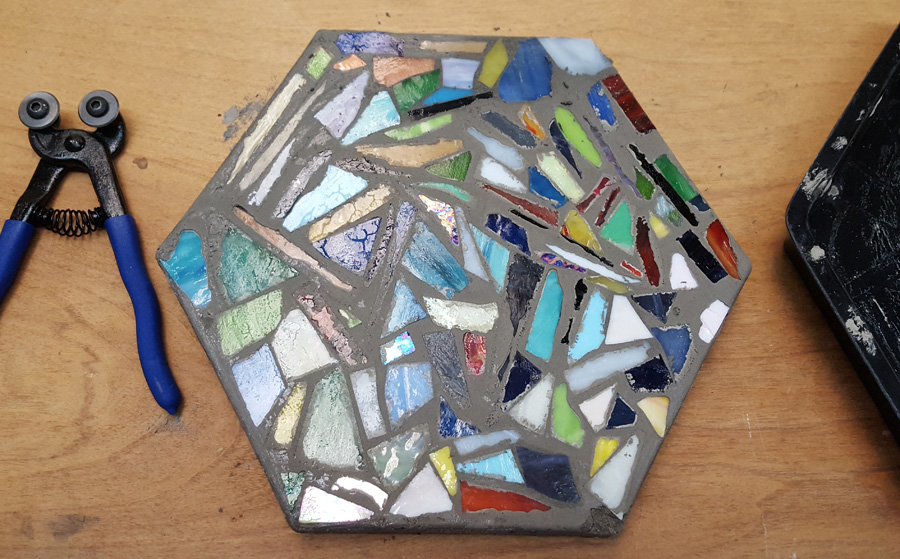

If you work with stained glass over time you can end up with buckets full of scrap. When the pieces start getting too small and irregular, or if there’s just too much of it, you can used them in a stepping stone. This tutorial demonstrates how to make a stepping stone with an abstract pattern. You can also use tiles instead of stained glass scraps.

Step 1. Remove Sharp Edges and Points

Stained glass shards are sharp and dangerous by nature; you don’t want to get hurt by walking on a sharp shard. Therefore it is necessary to trim the sharp corners off of any scrap glass you want to use in the stepping stone.

The mosaic glass cutter we sell is ideal for quickly trimming glass shards. It took just a few minutes to clip all the sharp corners off of this tray’s worth of scrap glass. The edges can still be quite sharp, especially when the material being cut is stained glass. A marble file is recommended for smoothing the edges of pieces going into a stepping stone.

Step 2. Prepare the Mold with Petroleum Jelly

Once you’ve got your glass ready, prepare the mold. The inside of this mold has been wiped with petroleum jelly. If you want to use contact paper to hold the design in place you can put that at the bottom of the mold instead of the petroleum jelly, but you’ll still need to wipe the sides of the mold.

Step 3. Position the Tile

This example uses a random assortment of glass pieces, but you can obviously choose to make an actual design. Again, if you have a particular pattern use contact paper in the bottom of the mold. In either case, make sure everything stays about a quarter inch away from the edges.

Step 4. Pour in Thinset or Concrete

This stone uses a blend of thinset and pea gravel. The thinset is tougher than ordinary concrete and will adhere more strongly to the glass.

The thinset was mixed with a little extra water in order to make it less sticky. When you pour the thinset into the mold on top of the design it can accidentally push the tiles around. Using a more liquid mixture lets it flow around the tiles or glass instead of just pushing them around as its poured. But this isn’t as much of a problem if you use contact paper.

Once you have the first layer of thinset down pour on a layer of pea gravel. Then mix some more pea gravel into the remaining thinset in the bucket. Pea gravel is nice because it strengthens the stepping stone and reduces the amount of thinset required. Fill the mold with the rest of the thinset-pea gravel mixture.

The mold is full. At this point you should wait at least 24 hours for the curing process to make the stone hard.

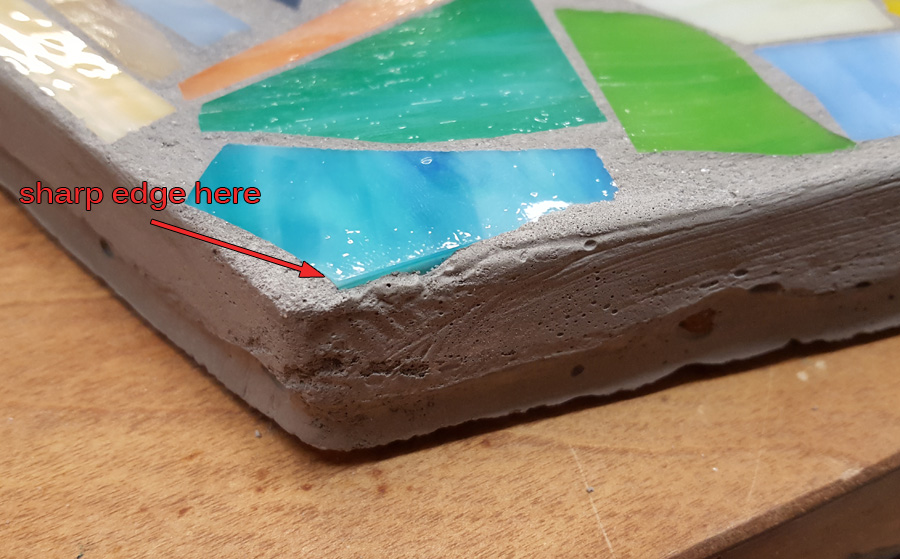

After 24 hours you can remove the stone from the mold. This one was mostly hard, but a corner got chipped. Also, you can see a couple of problems. In a couple places the edges of glass pieces are exposed along the edge of the hexagon, and the lines between the tile in some spots flowed on top of the tiles.

Start by cleaning the lines between tiles. Paper towel was used here, but you can use old rags or whatever is at hand. The material was still a little weak at this point, and in general thinset left on top of a tile isn’t in a strong position and it can be knocked out of the way by rubbing.

Once the lines were cleaned up the broken corner needed to be fixed. Mix a small amount of thinset and applied it to the corner. Leaving the stone to harden for 2 or 3 days instead of just 1 day before pulling it out of the mold would probably have kept the corner from chipping, but that would also have given the the lines between the glass pieces time to harden as well. The thinset wants to creep under the surface of the glass pieces when it's still liquid inside the mold.

Use your fingers to smear thinset into the broken corner and then try to shape it as best you can to match the other corners.

EDITOR’S NOTE: THINSET, GROUT, AND OTHER CONCRETE PRODUCTS ARE MILDLY CAUSTIC AND RUBBER GLOVES ARE RECOMMENDED FOR HANDLING IT. Nevertheless, wet concrete isn’t nearly as irritating as bleach or ammonia or any number of household cleaners, and that is why you can routinely see workers touching it with their bare hands. It will dry your skin out and leave it dry and cracked and chapped though, so gloves are recommended.

The final problem remaining was the exposed sharp edges. You can see in the above photo that this piece of glass is too close to the edge of the hexagon and it has a sharp edge exposed. This can be a safety hazard so we need to correct it.

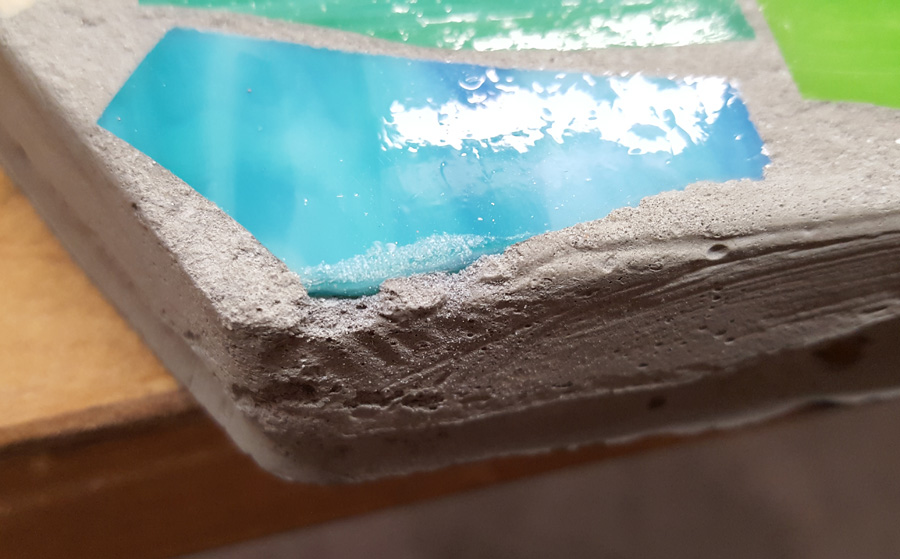

Use a rounded ceramic and marble file to smooth down the edge. You can also use the other file we sell, but the rounded one is probably easier for this purpose because it has a finer grit. Wear safety glasses when filing glass in this fashion, and be gentle with the file. You just need to round the edge enough that it isn’t sharp.

This edge is safe now.

Because the corner was repaired with thinset extra wait time was needed before sealing the stepping stone. One day should be fine, but to ensure the whole stone is completely cured it is good to allot 3 or 4 days for curing, which is what was done for this one.

The sealer used in this tutorial was found on the shelf at a big box home improvement store. It’s just a wipe-on/wipe-off silicon-based pore sealer and not some sort of coating. (We recommend traditional tile and grout sealers not coatings.) This particular brand didn’t leave any weird residue, but even if it had, the glass is non-porous, and the residue could have been wiped off.

A day later, with the sealer dry, this stone was done! Now all it needs is a home out in the garden.

Leave a Reply