Artist Catherine Augustus recently installed some mosaic medallion insets in the floor of St Clare of Assisi Catholic Church on Daniel Island, South Carolina, and you might want to take a look.

These mosaics were a volunteer project for the artist and her team of parishioners. They learned on the job and had to dance around some technical mistakes, but the results are great.

It’s problematic for me to publish an article about this particular mosaic installation because we can’t restock the porcelain mosaic used in it, at least not right now, and we might have to replace those product lines eventually.

This mosaic project is also problematic for me to write about because I haven’t made peace with the idea of putting an epoxy clear coat over a mosaic, and some of the work methods were improvised.

While I often use improvised methods, I’ve noticed that when these are shared online, too many readers assume that the method is standard because it is documented and has photos.

The reason I have to share these mosaics in spite of my concerns is that the art is well done. The medallions are all iconic designs that catch the eye.

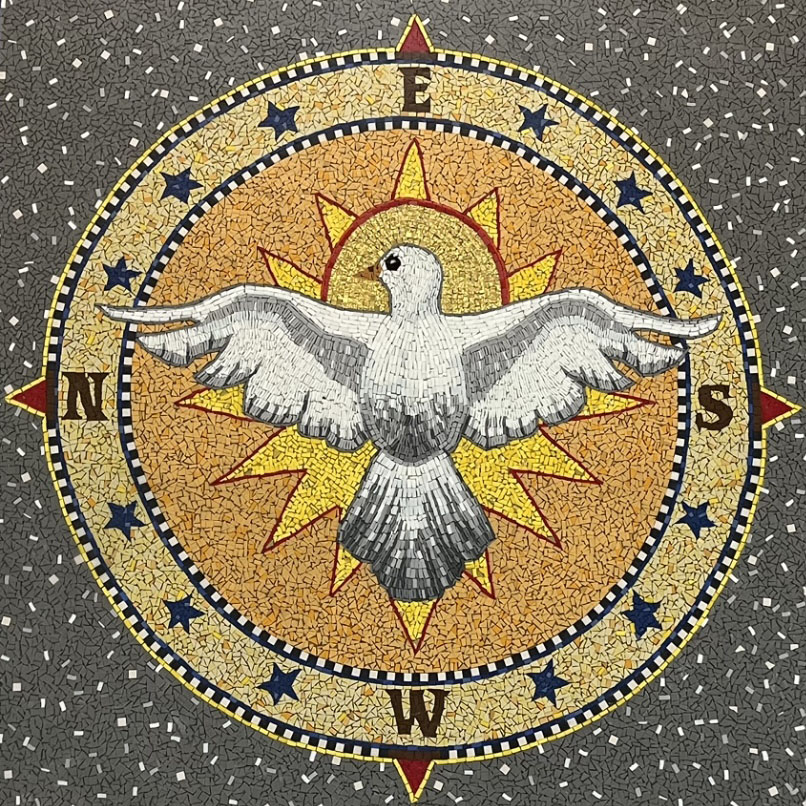

Look at the largest of the three mosaics:

The blue and yellow color scheme has excellent warm-cool contrast and is actually more sophisticated than it appears at first glance:

Notice the multiple hues of yellow/gold and the restrained use of the deep crimson and green.

There is detail and visual interest that pulls the eye in further.

The compound border is great in this regard, and the floral elements in the central icon seem to have just the right level of detail to make it the focal point.

Why Epoxy

Catherine needed an epoxy clear coat to level the finished surface of the mosaic because she used porcelain materials of different thickness.

I suppose that if you planned on using an epoxy clear coat, then you wouldn’t have to limit yourself to porcelain and stone but could use glass mosaic tile instead, which is much cheaper and more colorful.

Our glass mosaic tile isn’t recommended for commercial flooring, but under an epoxy clear coat rated for commercial flooring, it would be fine.

Joe’s Epoxyphobia

Of course people install epoxy floor coatings all the time. In fact, epoxy is the toughest all-around-best material for a durable stain-resistant floor.

But modern building materials like epoxies, silicones, and caulks have life expectancies of decades not millennia.

Epoxy isn’t an archival material. It can contract, crack, and turn yellow over time. The material itself is vulnerable to degradation by UV light and solvents. There is also an issue with fine scratching and tiny particles of dirt getting embedded in the surface over the decades.

A large part of the ethos of mosaic is art as ancient relic, something made to last for millennia.

A coating that will need to be replaced at some point might age in a way that distracts from the “timeless” look of the mosaic. That’s my big hesitation.

Yes, you can use epoxy floor coatings over a mosaic, but I’m not making that statement as a general recommendation.

The content of this blog must emphasize best-practices from a fine-art perspective. Think mosaic icon instead of mosaic floor.

You definitely wouldn’t want to coat a small work of mosaic art because the textured surface is a big part of the medium’s appeal.

Mosaic Medallions

I’m impressed that a team of volunteers figured out how to make and install these mosaics and that they did such a good job.

For starters, the mosaics are large: 52×52 inches, 6×7 feet, and 8×8 feet.

The standard method for mosaics this large is to cut the mosaic up into sheets for transport from the studio to the site of installation.

This requires that the sheets be carefully aligned when installed, and that’s why medallions smaller than 3 or 4 feet will usually be left uncut as one whole sheet.

But not mosaics larger than that.

Once the mosaic is larger than 48 inches, the reasoning is that the effort of carefully aligning the sheets of a cut-up mosaic is less work than handling something that large.

Catherine says they transported these large medallions whole by bolting them between sheets of plywood reinforced with steel beams and using 8 stout volunteers to get it on and off the truck.

These custom plywood pallets were used to slide the mosaics off into the thinset mortar, and that also required coordinated lifting by a team of many people.

It’s difficult to handle something that large and heavy even when you have many volunteers, and so the standard method of dividing the mosaic up into sheets would have made this part easier.

TIP: Standard methods make things easier, especially for large projects. Plan for scalability.

I love stories of here’s how I did something awkwardly and managed to succeed and made good art.

A lot of my favorite art that I have made has that element.

Team Spirit

I also like that this project was done by volunteers and that they worked through all sorts of difficulties including COVID over a five-year period.

Catherine say the work was done on tables in her garage:

“We used car mechanic light stands for extra light and heat during the winter months and a dehumidifier and fans for cooling during the summer months.”

I can relate. We’ve had projects so large that they were executed on the sheet-metal loading dock, and some of these were in the summer when only night work was possible.

It’s amazing what you can work through when the art bug bites.

Still, the fact that the volunteers could rise above technical missteps and other frustrations says a lot about the parishioners and their ability to work as a team.

Mixed-Media Mosaic

In the photo below, a torch is used to get rid of bubbles in the epoxy resin.

Look at the detail of the sky in the lower left of the photo and notice how the blue tile used to render it is different sizes and thicknesses.

That is one positive thing about the epoxy clear coat: the texture might not be felt, but it is definitely seen.

You could produce a similar mix of sizes using a blend of glass mosaic tile in 12mm and in 20mm.

The 12mm glass mosaic tile can also be cut in half and mounted on edge for a “cleaved-face” appearance similar to smalti.

Porcelain Shortage

We can’t restock our porcelain and ceramic mosaic products right now.

The President invoked anti-dumping penalties on Chinese-made ceramic mosaic of all types in 2019, and our small colorful tiles got lumped in with large ceramic floor coverings, which were the dumping problem that was being targeted.

These penalty tariffs are in addition to the 25% tariffs placed on most materials and parts from China in 2019. They are many times the cost of the merchandise.

I keep thinking this will change because the small colorful tiles we carry aren’t produced in the US and haven’t been for decades if ever.

Leave a Reply