Tag: troubleshooting

-

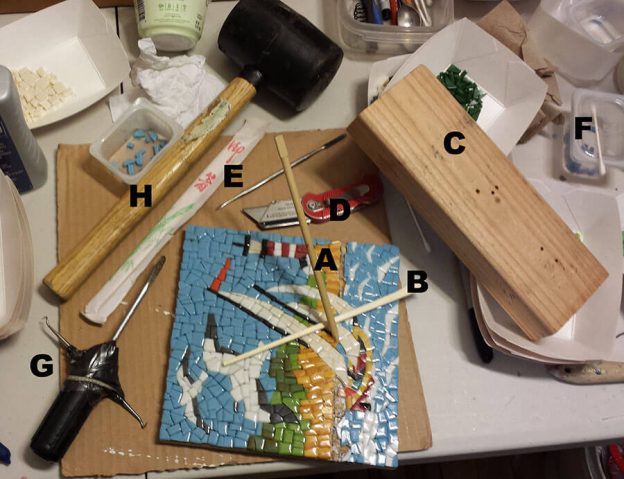

Box Turtle Mosaic

This mosaic was made on a temporary surface of clear contact paper. I looked at the shell patterns of countless Eastern Box Turtles. The shell pattern of the turtle in my mosaic is all of them and none of them. I had an interesting problem with the backer for this mosaic. I found a way…

-

The Beauty of Cheating in Art

As artists, we are often hypercritical of our own work and can only see the flaws in our art. Often times these “flaws” are details not even noticed by the viewer, and when the are noticed, they aren’t even perceived as flaws. However, sometimes we really do screw up a detail in an otherwise perfect…

-

Sizing Your Mosaic

Once you have a design you would like to create in mosaic, the next step is to determine how large to make it. The minimum size a mosaic can be is determined by the finest detail to be depicted in the image. I recommend trying to render that one finest detail first to determine if…

-

How To Pry Up Tiles To Modify A Mosaic

I have often used a small screwdriver to pry up tiles when I wanted to change some detail in a mosaic, but in all of those cases, the mosaic had a grout gap, and it was possible to knock an individual tile out or shatter it without damaging its neighbors, at least most of the…

-

The Importance of Contrast: Mosaic Sign Case Study

Contrast is critical for creating images that catch the eye and text that is readable. A mosaic sign recently completed by Ann Mitchell is a great example of the importance of contrast and the rewards of looking at your work in an objective way and reworking problem areas.

-

Staining Grout With Acrylic Paint

Mosaicists sometimes mix in artist acrylic paint to create custom colors from white grout, but you can also use acrylic paint to “stain” grout after it has hardened (for dry indoor mosaics). Like the process of staining wood, “staining” grout with paint is a process of wiping on and wiping off. The paint sticks to…

-

Grouting Case Study (Plus Mosaic Art Worth Seeing)

Artist Sherri Grasmuck created a mosaic facade of Guatemalan women on her house in Philadelphia that is the perfect case study for choosing a grout color.

-

Why Did My Tiles Come Loose From Thinset?

Recently, artist Jackye Mills emailed me about a problem she was having with her first mosaic project, and it really caused me a lot of angst because the artwork was a strong design that was otherwise well executed. I hated the thought that a first-time mosaicist could do such a good job on something so ambitious only to…

-

How to Cut Diagonal Triangles from Vitreous Glass Tile

Many people report having trouble cutting vitreous glass mosaic tile reliably because of the embossed patterns on the back sides, which can interfere with the blades of the mosaic glass cutter, but if you take simple steps to minimize interference and rotation, it can be done. What I mean by interference is when the blade slips…

-

How to Build Up Areas and Fill Holes in Mosaic Backers

For dry indoor mosaics, areas can be built up to support thinner tile next to thicker tile by mixing sand or sawdust to Weldbond adhesive to create a heavy paste. You can also fill holes in mosaic backers using this method. Sand is best for minimizing the contraction that happens as the glue dries, but sawdust…

-

Matching Grout to a Room’s Color Scheme?

Choosing a grout color is more of a situation where you want to avoid making a mistake that causes the tile to look wrong than it is an opportunity to tie in the room’s color scheme by selecting some optimal color. A Case Study Should you match grout color to a room’s color scheme? Not necessarily. Making…

-

Gaudi Mosaic Bench Freeze Damage

A few years ago, Karen J created a mosaic bench in her backyard using mining debris (large stones), cement, and chicken wire to form the base, which is similar the methods we recommend in our instructions for creating bases for outdoor mosaic sculptures. Karen modeled her bench after those made by the great mosaic architect…