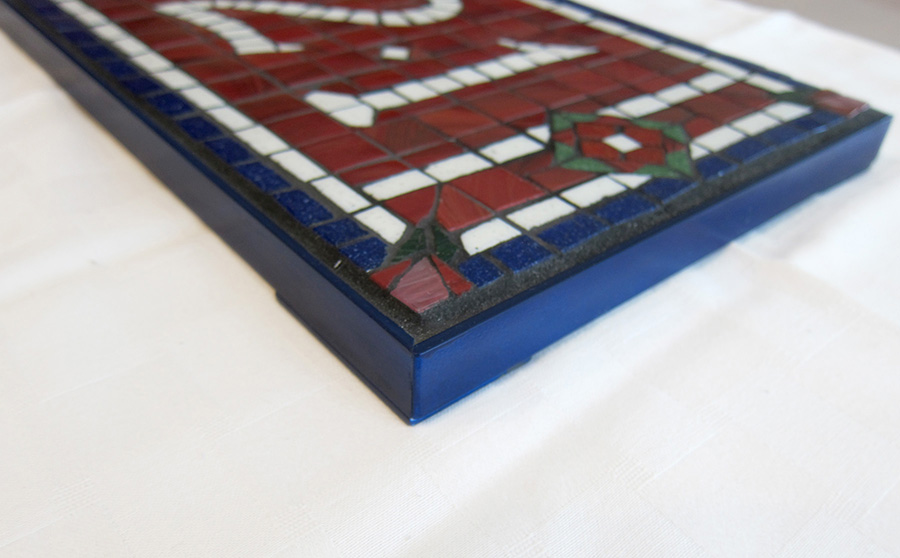

Artist Brad Srebnik’s mosaic street number plaque is worth taking a look at for several reasons. It has a harmonious color scheme with good warm-cool contrast, it’s tightly executed, and the numerals have crisp outlines and subtle curves in a distinct font style.

If you are thinking about a project with mosaic numerals or letters with any kind of calligraphy or distinctive font, this mosaic has a lot to show you.

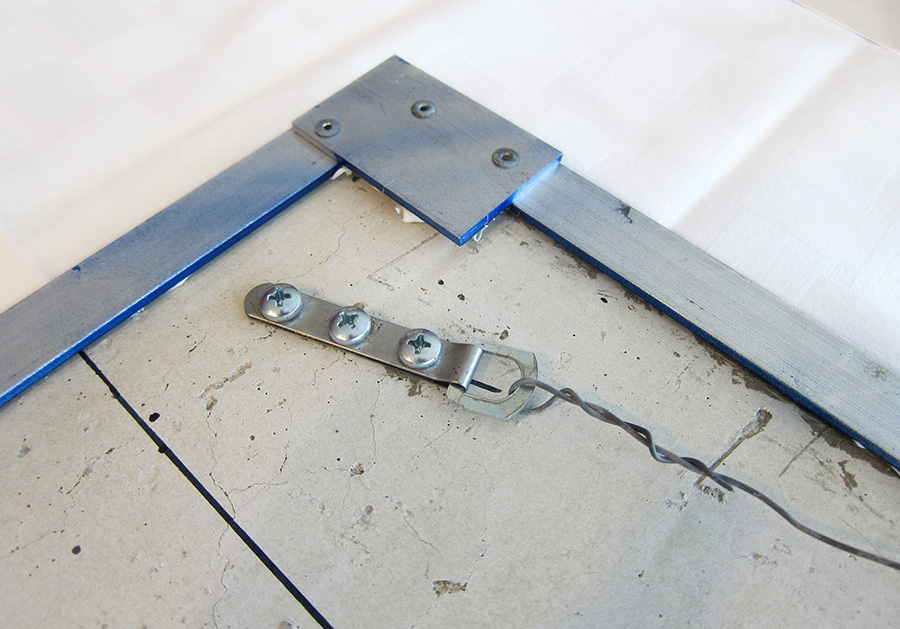

Brad also did a good job photographing the work in progress, including the method he used for mounting the hanging wire.

I wanted to show Brad’s method of hanging the mosaic and also make some points about how to make his hanging system more secure.

Keep in mind that the preferred method of mounting a mosaic is to have mounting holes in the mosaic’s integrated frame or through the mosaic backer, which is what would be required on most commercial buildings.

The french cleat method of hanging a mosaic is another secure alternative to hanging wire systems. Wires are more vulnerable to corrosion than fasteners and cleats, and a french cleat can distribute the load between multiple studs inside the wall.

Of course, french cleat systems for outdoor mosaics should be made of metal not wood.

Brad’s Method

With the help of a friend with a chop saw (power miter saw), Brad cut up pieces of aluminium L-stock, which they pop riveted together using square pieces of aluminum flat stock as rivet plates at the corners.

Brad said he painted the frame and that it took something like 11 coats to get it even.

If the frame were steel and not aluminum, that might have been a good idea for corrosion resistance alone (Seattle climate), but Brad was painting the frame for aesthetic reasons.

You can look at how tightly executed the mosaic is with its distinct font and know that the artist is the kind who would paint the frame 11 times just to make it look right if that is what it took. 🙂

For the past two decades, we’ve received many unhappy emails about mosaic problems and failures, and so we don’t mind speaking bluntly if we think we can keep you from grief.

The wire hanging system Brad used should be improved in 2 ways, especially given the rainy local climate.

Improved Hanging Method

The hanging wire on the back should be multi-stranded or have redundant wires or both.

Sometimes dissimilar metal corrosion can happen very quickly, sometimes amazingly fast. Rainy Seattle is definitely a place where rapid corrosion happens.

Fun Fact: Dissimilar metal corrosion is what powers batteries. What that means is that you can have parts made of different types of metal corrode each other in the same sort of time it takes for a battery to run down, especially if one of the metals is thin.

I recommend using the multi-stranded stainless steel wire made for picture hanging. The wire is usually the thinnest metal piece in the system and therefore the most vulnerable to failure. Best it be stainless steel.

Fasteners in Concrete Backer Board

Fasteners for hanging wires are a point of failure over time if they are inserted into concrete backer board.

From our own observations and customer reports, we have noted this problem with short screws in concrete backer board no matter how secure or tight they might be initially.

Why this happens is that small back-and-forth movements due to wind (or handling) cause vibrations that crumble the concrete around the threads in tiny increments.

Unlike wood and compressible materials, concrete has very little tensile strength and is brittle, and so it just doesn’t hold fasteners in the same way. There is no “springiness,” and a little bit of movement or vibration can quickly work a fastener loose.

My apologies for belaboring this point, but I want to convince as many people as possible that they shouldn’t trust short fasteners without adhesive in concrete backer board.

Mosaics tend to shatter when they hit the ground.

A Quick Fix

Fortunately, there is a quick and easy was to address the problem with screws pulling out of concrete backer board.

I cut a small square of hardware cloth or fiberglass mesh, and plaster this over the screw heads with thinset mortar. Once this hardens, those screws aren’t going anywhere.

This fix is something that can be done retroactively the next time you have some mortar mixed up for a different project.

Leave a Reply