Category: Step by Step Instructions

-

Broken Millefiori Mosaic Coaster

I made a mosaic bouquet coaster using our Broken Millefiori and Morjo 12mm Recycled Glass Tile. I used clear contact paper to lay out my design so that I could improvise without a pattern and make revisions as desired BEFORE glue is involved. I wrapped the contact paper around the backer temporarily so that the…

-

Marble Mosaic Restoration Project

At the end of 2019 Mosaic Art Supply was e-mailed by a local homeowner about repairing a stone mosaic that was being displayed outdoors. The design of the mosaic is a smaller-scale interpretation of the “Tree of Life” mosaic found in the bath of Hisham’s Palace in eastern Palestine. The palace dates to the 700s…

-

Color Constraints and Background Colors

Many artists like to choose background colors after the central figures have been tiled. It is best to tile from the middle and work toward the edges to avoid awkward spacing between at key focal points, but you should not leave the color choices for the background as a complete afterthought. Nor should you have…

-

Changing Grout Color With Paint

The following method is only recommended for dry indoor mosaics. Artist Megan Adams recently used it to save a mosaic that had been compromised by white grout, which makes tile colors look less intense and the mosaic as a whole “bleached out” in appearance. We put white grout in bathrooms because it is used as…

-

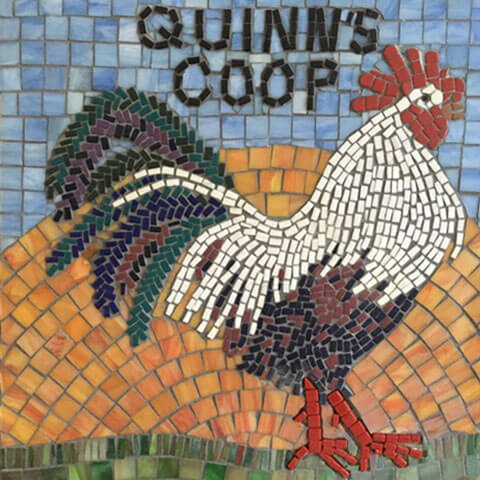

Making Foam-Core Mosaic Backers For Outdoor Projects

Artist Jill Gatwood uses the following method to make water-resistant foam-core mosaic backers for exterior mosaics, such as the Pet Memorial Name Plaques she does for clients who need something that is lighter weight and easier to ship than stone or solid concrete. The method wraps the foam in three or four successive layers of…

-

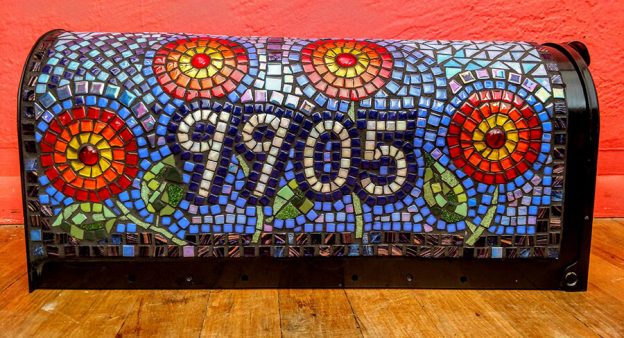

Mosaics on Steel Mailbox Using Silicone Adhesive

Artist Jill Gatwood has emailed me her procedure for using GE Silicone II to mount mosaic tile to steel mailboxes, and it is outlined below. Jill’s instructions have convinced me that there are enough mosaic applications for silicone adhesive that we should sell it. Note that we still recommend thinset mortar or Weldbond for mosaics…

-

How To Pry Up Tiles To Modify A Mosaic

I have often used a small screwdriver to pry up tiles when I wanted to change some detail in a mosaic, but in all of those cases, the mosaic had a grout gap, and it was possible to knock an individual tile out or shatter it without damaging its neighbors, at least most of the…

-

How to Cut Diagonal Triangles from Vitreous Glass Tile

Many people report having trouble cutting vitreous glass mosaic tile reliably because of the embossed patterns on the back sides, which can interfere with the blades of the mosaic glass cutter, but if you take simple steps to minimize interference and rotation, it can be done. What I mean by interference is when the blade slips…

-

How to Make a Stepping Stone with Scrap Glass

If you work with stained glass over time you can end up with buckets full of scrap. When the pieces start getting too small and irregular, or if there’s just too much of it, you can used them in a stepping stone. This tutorial demonstrates how to make a stepping stone with an abstract pattern.…

-

How to Hang Mosaic Art with French Cleat Wall Mounts

Small mosaic plaques can be mounted on a wall with a the same type of hangers and wires used for paintings provided the nail on which it hangs is mounted in a stud inside the wall, and even then redundant wires and fasteners are recommended. However, larger mosaics need more robust mounting hardware. The “french…

-

How to Build Up Areas and Fill Holes in Mosaic Backers

For dry indoor mosaics, areas can be built up to support thinner tile next to thicker tile by mixing sand or sawdust to Weldbond adhesive to create a heavy paste. You can also fill holes in mosaic backers using this method. Sand is best for minimizing the contraction that happens as the glue dries, but sawdust…

-

Matching Grout to a Room’s Color Scheme?

Choosing a grout color is more of a situation where you want to avoid making a mistake that causes the tile to look wrong than it is an opportunity to tie in the room’s color scheme by selecting some optimal color. A Case Study Should you match grout color to a room’s color scheme? Not necessarily. Making…